Defense Electronics and Solar Defenses Solution

Strategic Electronics Business Unit (SEBU)

RTC has expertise in the field of Defense Electronics, and has been able to establish a strong position in design, development, manufacture and integration of rugged Military grade electronic hardware and systems on turnkey basis. These include complete electronic packages for multi-axis motion control systems and embedded controllers for weapon launch platforms.

RTC has developed an expertise in Environmental Control & Fuel Monitoring System & Video cards for Light Combat Aircraft being developed for the Indian Air Force.

To cater to this, Strategic Electronics Business Unit (SEBU) was established in Delhi to augment RTC’s electronics capability in the Defense and Aerospace areas. The areas of focus of the SEBU include Avionics, Military Communication, and Simulators for Military Equipment, Electronic Warfare, System Integration and Satellite Assembly, Integration & Testing [AIT]. SEBU range of products also includes subsystems & board level solutions, besides life cycle support for design & development of Avionics LRUs (Hardware & Software) for military aircraft & airborne systems.

SEBU is responsible for design, development and manufacture of Electronic Modules, Subsystems and High End Microelectronic Circuits. The products designed and manufactured are primarily for the Defense, Aerospace and Space segments.

The Engineering capabilities at SEBU cover Conceptualization, Architecture and Schematic Design, CAD, Simulation, Optimization, packaging design and test system design all of which are done using standard and custom built tools.

The Manufacturing technologies of SEBU cover Thick & Thin film microelectronics, SMT/Mixed PCBA and Box build and environmental screening facilities complying to MIL, SPACE, ESA and JSS standards.

The manpower is trained to workmanship standards like J-STD-001, IPC-610-Class3 and ISRO standards.

The products cover Electronics for Inertial Systems, Solar application, Sensor and transducer interface, BLDC Controllers, Electronic Delay Units, Laser Receivers, DC-DC Converters, Microelectronics, Power processing units, Multiplexers, Voltage to Frequency converters and Signal conditioners

Defense Electronics

RTC is India’s leading Electronics Industry partner for Defense Electronics and is engaged with all the major Global and Indian customers in Defense Electronics. Products are developed and delivered in Built to Specification (BTS) and Built to Print (BTP) mode. RTC is eligible for the Defense offsets and has the Industry license for the manufacture of Electronics and Communication products for military use. Since 1998-99, RTC has been engaged in the development and productionisation of modules, subsystems for missiles, radars and military communication applications for DRDO laboratories and Defense PSUs. The manufacturing lines at RTC including the independent and approved reliability test house comply with the requirements of MIL-STDs.

Power Products

RTC specializes in Power Electronic products for Hi-Reliability segments like Defense, Space and Industrial. The design and engineering team has members qualified with Bachelors and Master’s degree in Power Electronics areas.

Some of the Power products designed, developed, qualified and products ionized are:

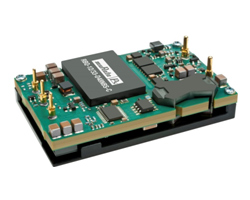

DC-DC converters and DC Power Supply (Solar and Non Solar)

AC-DC converters and DC-AC inverter

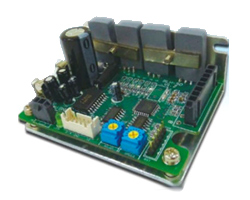

BLDC Controllers

- Topology Selection

- Circuit Design

- Magnetics Design (including Planar Magnetics)

- Simulation.

- Component Selection.

- Layout Design for PCB and Planar Magnetics.

- Packaging

- Proto Development & Testing (including the Environment tests).

- Solar power system design and calculation.

- LED subsystem and optics design.

- Sensor interface and close loop control design.

- Re-Engineering.

- Prototyping and sample preparation.

- Reliability study and design calculation.

- De-rating.

- RoHS

- Part Stress Reliability Analysis

- Loop Stability Simulation and Measurement

- Thermal Analysis

- Structural Analysis

- FMECA

- DFMEA

- FMEA

- DFM

- Feasibility Analysis

- DC-DC & AC-DC Converters

- Output Powers ranging from few watts to few Kilowatts

- Single & Multiple outputs [Continuous and Switching outputs]

- Forward, Fly back, Push pull, Half Bridge, Full Bridge topologies with built in EMI filters

- Isolated Input-Output converters

- Realization of the power supplies using Hybrid only, Hybrid & PCBA technologies.